In an episode of Netflix’s sketch comedy present “I Assume You Ought to Depart,” Tim Robinson’s character Mike disrupts a piece assembly to speak about his patterned shirt from a retailer known as Dan Flashes. Mike explains to his coworkers that Dan Flashes sells males’s shirts with various patterns and that the costs mirror how difficult the patterns are.

Not fairly as comical because the shirt sample dialogue, client procuring patterns are including their very own stage of complexity to beverage supply.

Kevin McWilliams, director of main accounts at Yale Carry Truck Applied sciences, Greenville, N.C., shares how the various SKUs in shops has made distribution extra difficult.

“Merely put, shoppers have sought extra from their beverage choices — extra sizes, extra flavors and extra portions,” McWilliams says. “The truth is, beverage firms are introducing extra merchandise yearly than different main segments, that means extra SKUs for warehouses to course of, retailer and distribute. Shoppers are additionally anticipating larger comfort and swift availability of those merchandise each in shops and on-line.”

This locations larger strain on beverage operations to safe tools that may assist them improve the effectivity of their storage, choosing and supply processes, he provides.

Labor points are also impacting supply.

“Inside the 4 partitions of beverage distribution operations, warehouses face a tricky outlook, with persistent labor challenges threatening productiveness and risking security incidents,” McWilliams explains.

He factors to a current MHI Business Report, which famous that 52% of companies ranked hiring and retaining expert labor as a significant problem for his or her provide chains. The identical report discovered that 45% of companies ranked a scarcity of expertise as a significant problem.

“Similar-day supply can be turning into an expectation, making velocity and agility a precedence for operations, all whereas holding prices down amid inflation,” McWilliams says. “These buyer calls for have been ranked by 43% of companies as a significant provide chain problem, per the 2025 MHI Business Report.”

Streamlining the method

Warehouses cope with a wide range of challenges day-after-day, from a scarcity of operators to rising prices.

Yale’s McWilliams notes these components and says there are a number of methods telemetry knowledge can help in adjusting operations, relying on particular targets and challenges.

“For instance, if impacts are discovered to be extra frequent in sure areas, managers can make the most of this knowledge to rearrange their facility’s structure and scale back the danger of expensive impacts in the issue space,” he says. “If the information exhibits {that a} explicit operator is vulnerable to impacts, warehouse managers can organize for added coaching that reinforces correct working conduct and scale back the chance of future impacts.”

As working prices proceed to rise, McWilliams states that elevate truck utilization knowledge will help companies decide whether or not their fleet is the proper dimension and structured with the suitable combine of kit.

“In instances the place it’s decided the fleet is just too giant, operations can construction their fleet extra effectively going ahead and defend their backside line,” he provides.

Michael Bloom, director of linked options at Mitsubishi Logisnext Americas (MLA), Houston, shares how far telematics know-how has come. When it first began out, he notes that telematics was simply GPS monitoring, however issues shortly modified when companies started “asking higher questions.” Not simply the place is the car, however what’s it doing?

As we speak, Bloom feels that telematics is doing loads of heavy lifting behind the scenes, from digital proof of supply to images and signatures.

“Within the beverage business particularly, telematics is now embedded throughout your entire provide chain — from the plant to the distributor, to the supply truck, to the retail retailer flooring,” he says. “And it’s not nearly vans anymore. Adoption charges to be used with forklifts, order pickers, attain vans, arise counterbalance, pallet jacks and different materials dealing with tools are all on the rise.”

The next are a number of areas that Bloom has recognized the place telematics is “making an actual affect:”

- Compliance made simple: Duties like pre-shift inspections was once on paper, however now are digital, quick and auditable.

- Value management via visibility: Duties resembling monitoring how lengthy it takes to load a pallet, how usually a truck idles or how effectively a route is being run may be measured and managed, including as much as actual financial savings.

- Danger mitigation via automation: When a pre-shift inspection flags a difficulty, the system can routinely notify upkeep and disable the forklift to stop additional use. The tools stays locked till a supervisor or technician resolves the issue and reauthorizes operation, serving to guarantee security protocols are adopted.

- Operator accountability: Corporations can monitor operator certifications, ship alerts when renewals are due and even limit tools use to certified personnel.

- Proactive upkeep: As an alternative of reacting to damaged tools, now firms can schedule upkeep primarily based on utilization knowledge, decreasing downtime and elongating tools lifespan.

“Telematics began with location,” Bloom says. “Now it’s about perception. It’s serving to beverage supply firms not solely know what’s occurring — however what to do about it. That shift — from knowledge to decision-making — is the place the actual energy lies.”

Bloom shares his ideas on how telematics suppliers are using options like machine imaginative and prescient and synthetic intelligence (AI) in improvements.

“We’re in the course of a extremely thrilling shift — conventional telematics is merging with superior imaginative and prescient techniques and AI to offer firms a a lot clearer, real-time image of what’s occurring on the bottom,” he says.

Traditionally, Bloom notes that telematics has finished a great job of logging impacts, however with machine imaginative and prescient and AI, there may be video captured and replayed.

“Conventional telematics tells you one thing occurred,” he explains. “Video exhibits you precisely what occurred. It solutions the query ‘why’ one thing occurred and is like having an on the spot replay for occasions that happen inside the warehouse. That form of visibility not solely improves incident investigation — it’s a unbelievable coaching instrument.”

These new options are serving to telematics transfer from being reactive to proactive and even predictive, Bloom notes.

“We’re not simply accumulating knowledge anymore; we’re serving to prospects enhance their understanding of operator conduct, which permits them to assist mitigate dangers by coaching smarter,” he says. “It’s the place the business is headed and it’s occurring quicker than individuals may suppose.”

Equally, Yale’s McWilliams notes that the corporate’s Yale Imaginative and prescient affect digital camera, which is a telemetry accent, routinely captures and saves high-definition video footage of occasions three minutes earlier than and after an affect is detected by Yale Imaginative and prescient telematics.

“The answer gives warehouse managers with visibility they’ll use to assist enhance security, improve effectivity and scale back prices inside their operation,” he explains. “Even in harsh- and low-light environments, the digital camera will help warehouses to validate impacts and determine product injury and stock shrinkage points attributable to these impacts.”

As for different developments, McWilliams says the preliminary tier of the Yale Imaginative and prescient resolution turned a normal characteristic on quite a few key warehouse vans, together with order pickers, attain vans and turret vans.

“With this modification, extra operations may have the flexibility to raised perceive their whole value of fleet operations by monitoring their operation’s elevate truck utilization, impacts and site, in addition to assist defend towards expensive downtime by monitoring and scheduling preventative upkeep,” he shares.

MLA’s Bloom says the core of telematics has turn out to be “pretty commoditized,” with most suppliers providing variations of the identical fundamental knowledge set.

“The actual pleasure now could be round what comes subsequent,” he states. “We’re seeing the following technology of telematics transfer from merely accumulating knowledge to serving to individuals make smarter selections — quicker.”

One large shift Bloom notes is across the depth and relevance of the information. Moderately than high-level engine fault codes, he expects to see techniques floor detailed, application-specific diagnostics. Bloom makes use of the instance of rental fleet managers, who he says, “may have telematics tailor-made to their world,” from monitoring deliberate upkeep to automating the return and inspection course of.

“However the largest leap goes to return from AI — particularly, how we work together with telematics,” Bloom says. “Think about a world the place as an alternative of digging via stories, you simply ask, ‘Which of my forklifts are overdue for maintenances?’ or ‘Present me which operators may benefit most from some extra coaching — and for which subject areas?’ That’s what instruments like ChatGPT have opened individuals’s eyes to, which questions are the proper inquiries to be asking.”

Bloom states that, oftentimes, the reply to 1 query helps to determine the query one must be asking, however they by no means would have gotten there with out the primary query’s reply.

“We’re heading towards what I wish to name a ‘forkliftGPT’ mannequin, the place superior telematics platforms are layered with giant language fashions that allow anybody, no matter technical talent, extract insights from advanced operational knowledge,” he says. “It’s intuitive. It’s quick. And it’s highly effective.

“What’s much more thrilling is the flexibility to merge structured knowledge, like machine diagnostics and GPS, with unstructured knowledge, like coaching movies, name stories and even PDF brochures,” Bloom continues. “When you possibly can search throughout each varieties of knowledge, analyze patterns and join the dots — you unlock a complete new stage of worth.”

This shift goes to make analytics extra accessible, Bloom provides.

Enhancing operations

As operations acquire insights from telematics knowledge assortment, they’ll kind via knowledge factors to raised their operations.

To make the most of the information generated by elevate truck telemetry options, Yale’s McWilliams says operations should have the ability to simply entry, view and analyze that knowledge.

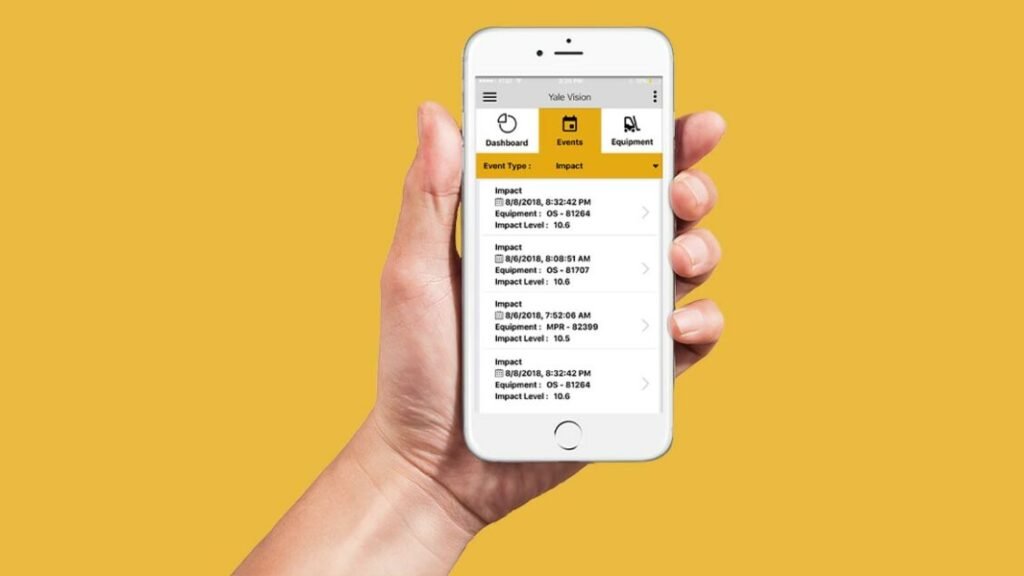

“The Yale Imaginative and prescient portal makes that attainable by presenting it in a sequence of easy-to-use dashboards that gives customers with full visibility from any internet-enabled gadget and permits warehouses to simply entry the information that’s most essential to them,” he explains. “A smartphone app can be out there to offer customers with insights into their fleet, together with computerized affect alerts and pre-shift guidelines notifications.”

On the resolution’s highest tier, McWilliams notes that customers can also use the app to manage operator entry, set off shutdown countdowns and look at the speeds of lively elevate vans.

“Moreover, Yale Imaginative and prescient is supplied to offer actionable insights with out additional knowledge sortation from the shopper, eradicating the guesswork from operators who might not be used to using such knowledge,” he says. “With its capability to observe and supply knowledge on tools diagnostics, the answer can acknowledge when potential points might come up and routinely notify customers that upkeep is required on that truck. Those that equip electrical vans with Yale Battery Imaginative and prescient can even obtain computerized notifications every time a possible battery challenge is detected.”

Earlier than investing in telematics options, McWilliams urges beverage-makers to contemplate their enterprise targets which have led to the purpose of in search of an answer. They need to determine particular downside areas they need to resolve, if any, and analyze how the fleet and operators are performing, he says.

“Having an thought of what telemetry ought to assist tackle is essential,” he provides.

Key areas McWilliams notes embody OSHA compliance, operator monitoring, preventative upkeep and tools utilizations.

“Objectives like these will help operators discover the best-fit telemetry choice to satisfy their wants — one which helps them keep away from paying for greater than essential or for an answer that doesn’t present the performance actually required,” he says.

MLA’s Bloom says that the most important factor he at all times tells individuals is that telematics knowledge is simply as priceless as their capability to do one thing significant with it. The very first thing operation groups ought to consider is the energy of the analytics engine, he shares, noting that if it could actually floor insights clearly, customers can discover what they want with out digging via dashboards.

“If the system can’t show you how to see the large image or spot the patterns that matter, you’re leaving loads of worth on the desk,” Bloom states.

The subsequent large consideration is integration, in response to Bloom. As a result of most beverage operations have a mixture of forklift manufacturers of their fleet, it usually means coping with quite a few telematics platforms, a number of logins and no simple manner of viewing all the things in a single place, he explains.

“In case your system can’t pull in third-party knowledge — or worse, if it locks you right into a walled backyard — you’ll spend extra time managing knowledge than managing your operation,” Bloom says. “In fact, any system you spend money on must cowl the basics: entry management, preventative upkeep, pre-shift inspections, engine hour monitoring, fault codes — all desk stakes at this level.”

With greater than 16 years on this house, Bloom has noticed this fact time and time once more: most firms use perhaps 20% of their telematics system’s capabilities. And that’s not a knock on the customers, he clarifies, however a mirrored image of how overwhelming these techniques may be.

“There’s usually a lot performance crammed in that it simply turns into extra noise,” Bloom says. “My recommendation? Don’t chase the platform with probably the most bells and whistles. Discover the one which nails the 20% you want and can really use. That’s the place you’ll see the most important return in your funding.”