In accordance with the most recent Worldwide Federation of Robotics (IFR) World Robotics 2025 U.S. corporations within the meals and beverage (F&B) sector have been feasting on versatile industrial robots, driving the variety of installations up by 21% in 2024.

However not all automation is similar, and the F&B sector has distinctive considerations and necessities, so slightly strategic considering can go an extended option to maximizing your automation investment.

Seen from a F&B perspective, the most important headline grabber from the IFR’s newest World Robotics report is automation adoption rising year-over-year by a surprising plus-20%.

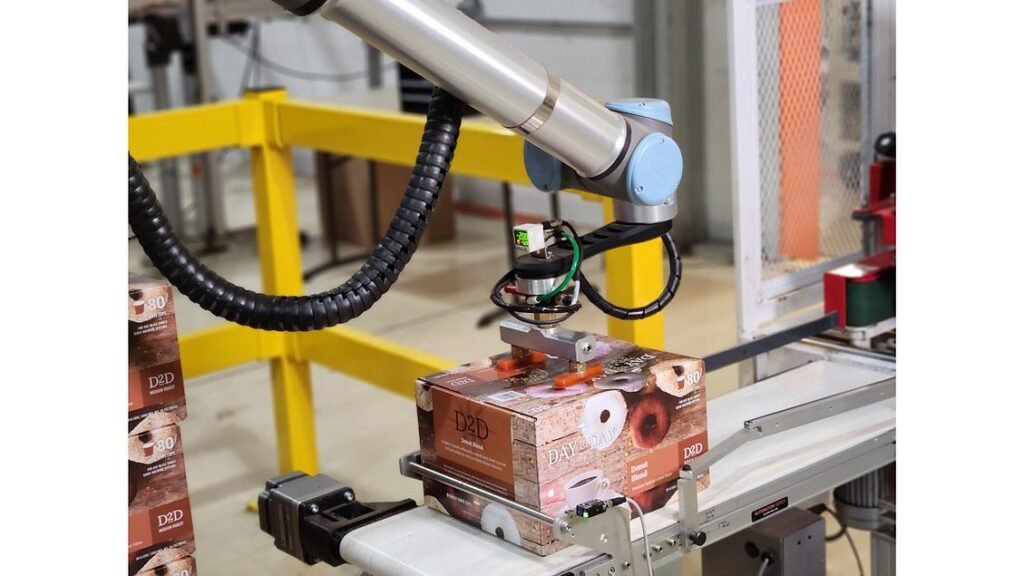

From pick-and-place, materials dealing with, and palletizing to labeling functions and from meals and beverage processing to packaging strains, robots are boosting productiveness and earnings throughout the nation’s F&B services.

This surge isn’t just about numbers — it displays a deeper shift in how packaging and end-of-line processes are being reimagined. Throughout the sector, producers are looking for methods to maintain tempo with enterprise calls for, and automation is more and more seen as the reply to packaging on the pace of enterprise.

How cobot-powered automation performs a task

In the meantime, the ‘Developments’ part of the IFR report notes the vital position of cobots in enabling corporations to automate such functions by way of easy-to-use, cost-effective automation with a small footprint that may be deployed subsequent to folks. And a case research on cobot-powered automated carton palletizing at a wine maker reinforces the advantages that cobots can convey from improved ergonomics to quick ROI. In accordance with firm proprietor, Volker Raumland, cobots “will unlock new alternatives for the wine trade.”

In fact, there are good causes to deploy cobots in any sector, however why have collaborative robots discovered such synchronicity with the necessities of the F&B trade?

For a lot of, the reply lies within the capacity to optimize every thing on the finish of the road. Clever automation options are actually able to maximizing uptime and productiveness, typically rising output by as much as 40%. These methods are designed to thrive in dynamic environments, dealing with frequent changeovers and high-mix product runs with ease —qualities which are important for F&B producers going through seasonal demand and shifting shopper preferences.

Dynamic environments for each season

Corporations within the F&B sector know all about dynamic manufacturing environments with excessive progress and excessive variability. Not like extra standardized industries reminiscent of automotive or electronics, F&B producers should continually adapt to altering shopper tastes, seasonal calls for, unstable raw-material prices, and shifting regulatory necessities round security and hygiene.

This churn leads to product runs which are typically shorter with frequent modifications. And this excessive combine setting requires automation with flexibility to match. It additionally implies that F&B corporations are searching for automation that may be each deployed and redeployed rapidly by non-experts with minimal downtime between modifications. Conventional automation stays a powerhouse for static, extremely repetitive duties, however can not compete with cobots in relation to speedy deployment, changeovers and suppleness.

Furthermore, in most F&B services, floorspace is at a premium, which implies corporations are searching for automation with a minimal footprint that may (following a threat evaluation) be deployed safely subsequent to people with none fencing. Resulting from their small kind issue and security options, cobots could be deployed in areas that conventional automation can’t attain, which creates alternatives for F&B corporations to implement automation in ways in which aren’t attainable with conventional options. By enabling flexibility, cobots present a quick manner for F&B corporations to spice up productiveness and high quality.

Future proofing operations

Confronted with labor shortages as its enterprise grew, espresso bean roasting and packing specialists Napco Manufacturers explored whether or not automation may help however discovered the price of conventional palletizing gear prohibitive.

“There’s a big barrier to entry once you’re speaking tens of millions of {dollars} in a single packaging line that will or might not provide help to,” says Eric Latsch, vp of pperations.

Napco turned to cobots as a substitute, as a result of decrease capital funding concerned, sooner ROI, and common ease of use. The corporate’s cobot palletizers run two shifts, working 18 to twenty hours a day. Every palletizing cell fills 1,500 bins, totaling 180,000 single-serve espresso cups packed each day between the 2 cells. Productiveness has elevated by about 15%. The corporate prevented the chance related to conventional automation investments. ROI was achieved in underneath a yr. Damage threat has fallen. And for eight shifts a day, people have been freed to concentrate on extra priceless duties.

As a result of Napco’s prices are actually fastened relatively than variable, and the system has considerably decreased additional time, the corporate is ready to be extra aggressive on bidding new enterprise.

“Having this automation with the next effectivity has made it attainable for us to amass new prospects. We now have a number of new private-label prospects that we couldn’t have dreamed of two years in the past,” Latsch explains.

Whereas conventional robots could be behemoths with huge attain which are able to dealing with huge payloads, cobots are not any slouches in both division.

The most recent technology of cobots brings extra than simply effectivity. With superior movement management, predictive analytics, and future-ready innovation, these methods are constructed to adapt and scale as enterprise wants evolve. For producers, this implies not solely sooner deployment and supercharged ROI, but additionally the arrogance that their automation funding will stay related because the trade continues to vary.

Automation hesitation not an element

Bob’s Purple Mill, an entire grain specialist primarily based in Milwaukie, Ore., deployed a cobot palletizing answer with a attain of 68.9 inch (1750 mm) to make sure that the robotic may deal with the 81-inch pallets used within the facility.

The answer, dubbed ‘miniPAL+’ handles as much as 14 instances a minute and the cobot’s 44.1pound (20 kg) payload permits the system to double-pick bins that every weigh between 4-10 kilos. And automation hesitation wasn’t an element amongst employees.

“The workers right here at Bob’s have been actually excited to see this palletizing know-how come to their manufacturing line; in case you are producing properly, all of us get a share of the corporate,” explains Nick Chow, engineering and fabrication supervisor at Bob’s Purple Mill. “Automation is vital in serving to us develop and share our earnings, whereas additionally decreasing accidents so all people goes dwelling safely.”

Because the sector continues to evolve, the flexibility to deploy clever, future-ready automation — options that aren’t solely environment friendly but additionally versatile and scalable — will likely be central to sustaining competitiveness. For North America’s meals and beverage producers, the message is obvious: end-of-line something, optimize every thing.