With shoppers anticipating extra from manufacturers immediately, packaging is tasked with not simply defending the integrity of drinks. Though this nonetheless is the final word purpose, model homeowners are turning to authentic gear suppliers to help the calls for of immediately’s buyers.

“Packaging tendencies within the beverage trade — like sustainable supplies, distinctive shapes, and smaller sizes — are driving the demand for versatile, high-resolution coding and marking gear,” says Giles Shepherd, strategic account supervisor at Videojet, Wooden Dale, Unwell. “Producers now require options that may deal with quite a lot of supplies, quicker manufacturing traces, frequent product adjustments, and sophisticated branding and regulatory calls for. With new fillers working at speeds of 80,000 to 120,000 cans per hour, coding gear should sustain with these greater manufacturing charges.”

For coding and marking gear, Russell Wiseman, head of world beverage options at Domino Printing Sciences, explains that the trade is influenced by the identical tendencies as the opposite markets.

“Firstly, sustainability has grow to be a basic requirement in fashionable manufacturing, together with the beverage trade,” he says. “Clients anticipate their suppliers and companions to take proactive measures to cut back their environmental influence. This encompasses minimizing waste, transitioning to recyclable or compostable packaging, and innovating coding applied sciences that help these supplies with out sacrificing efficiency.”

Consistent with sustainability efforts, Wiseman additionally highlights curiosity in options that improve vitality effectivity, cut back emissions, eradicate dangerous chemical substances in addition to logistic elements corresponding to decreasing mileage, optimizing routes, and decreasing the general carbon footprint ― all of which Domino works with its companions on to help.

“Sustainability has grow to be a basic requirement for Domino’s manufacturing prospects and is at all times a key consideration inside any Domino resolution,” he says. “We collaborate immediately with our prospects to fulfill their sustainability expectations via tailor-made, sustainable, and built-in options designed to deal with their particular wants.”

Videojet’s Shepherd additionally pinpoints the affect sustainability has on the event of recent age gear.

“Sustainability is driving important innovation in coding and marking applied sciences,” he explains. “Producers are searching for gear that minimizes waste, consumes much less vitality, and works successfully on sustainable packaging supplies like recyclable and biodegradable substrates.

“For instance, new UV laser expertise makes the Videojet 7920 laser able to delivering exact, high-quality marks on sure mono-material movies designed for simple recyclability,” Shepherd continues. “With ink-based coding options, there may be an rising concentrate on creating inks that don’t impede the recycling course of, supporting packaging circularity.”

Want for pace

Though sustainability is having a rising influence on coding and marking options, the ever-growing SKU lineups have positioned higher wants on packaging gear.

“As automation accelerates and manufacturing speeds improve, coding and marking methods are beneath strain to ship flawless efficiency at excessive throughput whereas sustaining code high quality and minimizing downtime,” Shepherd says. “To fulfill these calls for, smarter, self-monitoring methods with real-time diagnostics and predictive upkeep capabilities have gotten important. These superior options combine seamlessly with automated manufacturing traces, enabling speedy changeovers, constant output, and real-time high quality management.”

Domino’s Wiseman notes that automating coding processes has at all times been a key goal for the corporate and its fashions.

“Domino Automation and Designer are our software program instruments for centralized label administration and automatic deployment,” he says. “These options assist cut back downtime, eradicate human error, and simplify advanced duties. Consequently, producers expertise quicker changeovers, constant print high quality, and fewer waste on the manufacturing line. Designed to adapt to our prospects’ wants, these clever instruments present producers with the arrogance to fulfill immediately’s calls for and the flexibleness to sort out tomorrow’s challenges with ease.

“Manufacturing-scale operations have at all times been in excessive demand from our prospects, and we’ve persistently met their wants,” Wiseman continues. “Our lasers can code greater than 100,000 cans or bottles per hour, which interprets to 27.7 merchandise per second.”

All linked

Connectivity is one other facet impacting coding and marking gear.

“As synthetic intelligence (AI) turns into extra built-in into manufacturing, end-to-end connectivity is essential,” Domino’s Wiseman says. “Gadgets and methods throughout the manufacturing flooring should talk seamlessly to allow real-time information assortment, diagnostics, and automation. As an example, printers are actually anticipated to be remotely monitored, built-in into manufacturing execution methods (MES) or enterprise useful resource planning (ERP) methods, able to verifying codes, predicting upkeep wants, and guaranteeing print high quality ― all with out human intervention.”

Videojet’s Shepherd additionally notes the influence that AI may have on coding and marking gear.

“AI has the potential to play a transformative function in the way forward for coding and marking gear,” he says. “AI will assist to enhance effectivity, guarantee correct coding and marking throughout various packaging varieties, and help manufacturers in assembly regulatory and client calls for with higher flexibility and responsiveness.”

Though AI has positioned itself in being a future resolution for coding and marking options, consultants word that it’s not with out its challenges.

“Many beverage services nonetheless depend on legacy methods that lack the connectivity and information infrastructure wanted to help fashionable AI options,” Domino’s Wiseman says. “Retrofitting or changing these methods could be each pricey and time-consuming. Information safety is one other rising concern; as extra units grow to be linked and extra delicate info is gathered, it’s essential to make sure safe transmission and storage.

“Furthermore, vitality effectivity stays a paradox in AI deployment,” he continues. “Whereas AI helps lower the general vitality footprint of a plant, the servers, sensors, and cooling methods required to function AI fashions could be vitality intensive. This raises questions in regards to the web sustainability positive aspects, notably as corporations try towards carbon-neutral targets.”

Designed for the longer term

With all these elements affecting coding and marking options, suppliers are creating gear that may help producers’ targets.

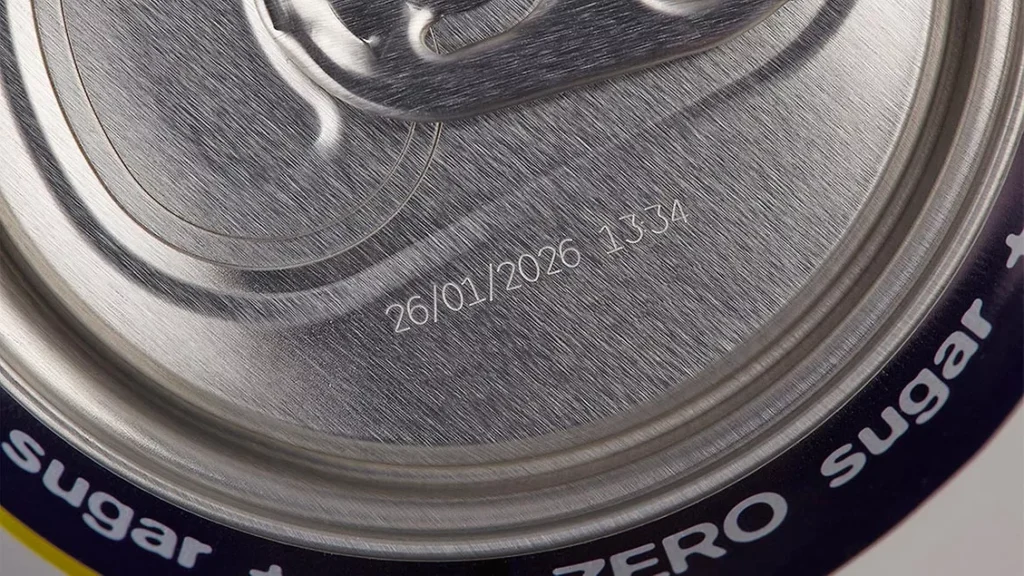

“Domino’s focus within the beverage sector is on creating built-in options particularly designed for brewers and beverage producers, serving to them deal with a myriad of challenges and alternatives, corresponding to implementing AI, optimizing and scaling up manufacturing, and guaranteeing they will meet their sustainability targets,” Wiseman says. “We’ve got lately launched BECCS (beverage empty can coding system) that codes cans earlier than they’re crammed. An progressive vacuum-based dealing with system suspends cans for exact, vibration-free coding, eliminating the necessity for can twisters or further guides. This ensures constant code high quality whereas simplifying changeovers and defending can integrity, even at speeds exceeding 100,000 cans per hour.

“However the advantages transcend pace,” he continues. “By discarding solely empty cans when errors happen, the system considerably reduces waste and value. Built-in with a real-time imaginative and prescient and rejection system, it might probably cease the system after 5 errors, stopping full-can dealing with and saving beneficial labor whereas minimizing disruptions. The result’s a wiser, extra sustainable operation that enhances effectivity, streamlines manufacturing, and safeguards profitability ― a great resolution for contemporary beverage traces.”

Videojet’s Shepherd anticipates that observe and hint capabilities in addition to laser coding for sustainability and permanence will grow to be a much bigger a part of the coding market.

“Producers are more and more adopting track-and-trace options to assist enhance provide chain visibility and cut back losses throughout recall occasions,” he says. “Sooner lasers with new wavelengths and sources can now mark a wider vary of packaging supplies immediately, creating everlasting, high-quality codes that improve traceability.

“… Laser methods are gaining recognition for his or her skill to supply sturdy, everlasting codes with out utilizing consumables like inks or solvents,” Shepherd continues. “This makes them a great alternative for a lot of recyclable and biodegradable packaging varieties and for supporting numerous sustainability efforts.”

Inkjet methods are also integrating sustainability attributes to their future expertise.

“New inkjet printer applied sciences embody options like ink recycling to assist cut back waste, decrease working prices, and help efficiency,” Shepherd says.

Future efforts to help sustainability targets may additionally have an effect on the labeling market.

“We’re collaborating with massive manufacturers to discover strategies for eradicating labels from bottles by coding all crucial info immediately onto the bottle floor utilizing laser expertise,” Domino’s Wiseman says. “We’re additionally exploring late-stage customization via digital printing, which incorporates printing QR codes that hyperlink to related info, for instance, on the bottle cap.”